Our Products & Services

P-Tech Automation for expert solutions in industrial automation, unparalleled customer service, innovative systems, and a proven track record of enhancing efficiency, reliability, and productivity in your operations.

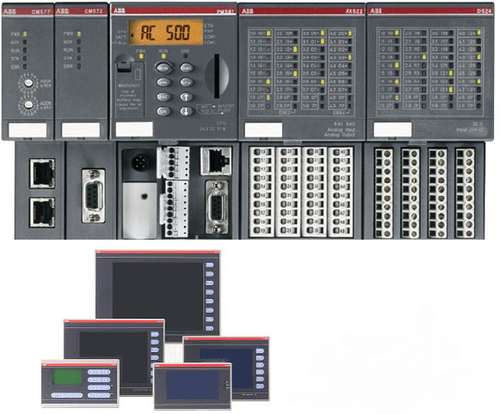

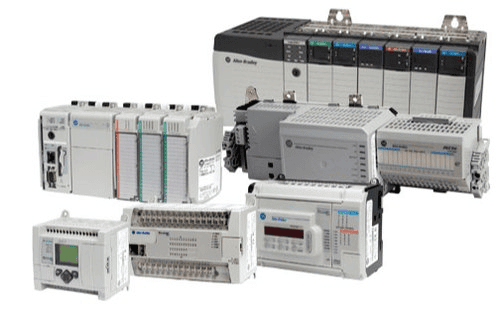

PLC & HMI

Programmable Logic Controllers (PLCs) are industrial digital computers designed for automation of electromechanical processes, such as control of machinery on factory assembly lines. They are highly reliable, capable of withstanding harsh industrial environments, and provide real-time processing. Human-Machine Interfaces (HMIs) are user interfaces that connect operators to the PLCs. They allow humans to interact with the machine, monitor processes, and adjust settings through graphical displays, touchscreens, or button panels. Together, PLCs and HMIs enhance efficiency, safety, and precision in industrial operations by providing seamless control and communication between machines and their operators.

Veriable Frequency Driv ( VFD )

A Variable Frequency Drive (VFD) is an electronic device used to control the speed and torque of electric motors by varying the frequency and voltage supplied to the motor. VFDs are crucial in applications where precise motor control and energy efficiency are needed. Here's a detailed description of how VFDs work, their components, and their applications:

PLC Panels

PLC (Programmable Logic Controller) panels are essential components in industrial automation. They house PLC hardware and provide a centralized control system for various machinery and processes. These panels enhance efficiency by automating repetitive tasks, improving accuracy, and reducing human error. Typically enclosed in robust, protective casings, PLC panels include power supplies, input/output modules, and communication interfaces. They can be customized to specific applications, such as manufacturing, energy management, and transportation. Integration with sensors and actuators allows real-time monitoring and control, ensuring optimal performance and safety. Overall, PLC panels are pivotal for modern industrial operations, ensuring reliability and scalability.

Mfg. Of Electrical Control Panels

Manufacturing of electrical control panels involves designing and assembling systems that manage and control electrical equipment. These panels include components like circuit breakers, relays, and switches, ensuring safe and efficient operation of machinery and electrical systems. Custom-built to meet specific industry requirements, they are used in sectors such as manufacturing, energy, and infrastructure. The process includes circuit design, component selection, wiring, and rigorous testing for quality and safety standards compliance. Skilled technicians and engineers ensure each panel's reliability and functionality. Electrical control panels are crucial for automation, energy distribution, and operational efficiency in various industrial and commercial applications.

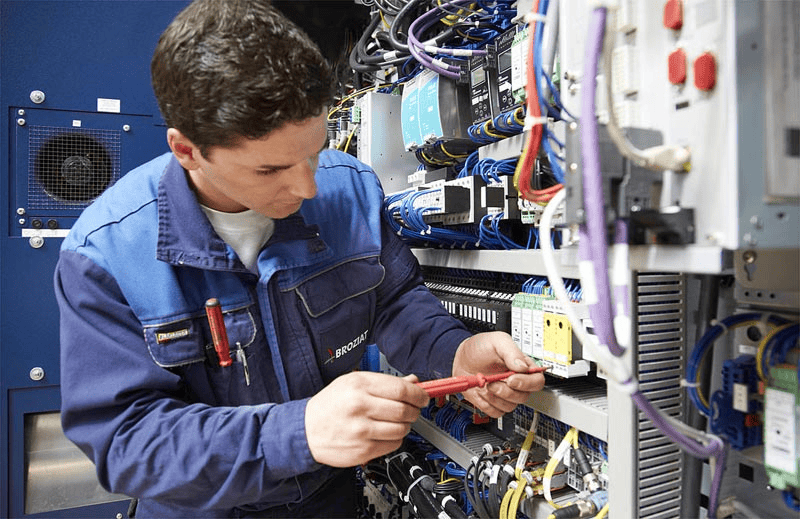

Onsite Service

Onsite service involves providing professional support and maintenance directly at the customer's location. This service is essential for addressing complex issues that cannot be resolved remotely, ensuring minimal downtime and optimal performance of equipment. Technicians or engineers visit the site to perform tasks such as installation, repairs, diagnostics, and routine maintenance. Onsite service benefits include personalized assistance, immediate problem resolution, and the opportunity for hands-on training and consultation. It's widely used in industries like IT, manufacturing, and healthcare, where specialized equipment and systems require expert attention. This approach enhances customer satisfaction by delivering tailored, efficient, and reliable support.

Installation & Commissioning

Installation and commissioning are critical phases in deploying new equipment or systems. Installation involves setting up machinery, electrical systems, or software at the customer's site, ensuring all components are correctly configured and safely integrated. Commissioning follows, with thorough testing to verify that the installed system operates as intended. This process includes calibration, performance checks, and fine-tuning to meet specified requirements. Skilled technicians or engineers oversee these stages, addressing any issues that arise. Successful installation and commissioning ensure the system's reliability, efficiency, and compliance with industry standards, paving the way for optimal performance and long-term operation.

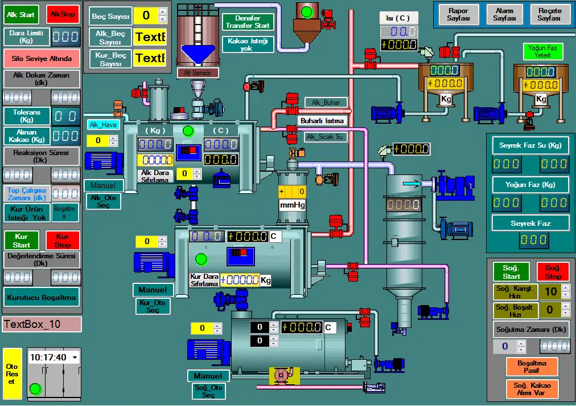

SCADA Programming

SCADA (Supervisory Control and Data Acquisition) programming involves creating software to monitor and control industrial processes. This programming allows operators to gather real-time data, control machinery, and manage operations remotely. SCADA systems integrate with sensors, PLCs, and other hardware to provide a comprehensive view of system performance. Key tasks in SCADA programming include developing user interfaces, configuring alarms, and setting up data logging and reporting features. Effective SCADA programming ensures efficient process management, quick fault detection, and improved decision-making. It is crucial for industries like manufacturing, utilities, and energy, enhancing automation, safety, and operational efficiency.

PLC Controllers

PLC (Programmable Logic Controller) controllers are robust, industrial digital computers designed for automating machinery and processes. They are integral to modern manufacturing and industrial operations, offering precise control, flexibility, and reliability. PLC controllers handle complex tasks by processing inputs from sensors and executing programmed logic to control outputs. Key features include real-time processing, modular design, and resistance to harsh environments. Used in various applications such as assembly lines, robotic devices, and power management systems, PLC controllers improve efficiency and reduce human error. Their programmability allows easy updates and scalability, making them essential for adaptive and efficient industrial automation.

Automation

Automation involves using technology to perform tasks with minimal human intervention, enhancing efficiency, accuracy, and consistency. It integrates systems like PLCs, robotics, and AI to control machinery, processes, and operations in various industries. Automation streamlines repetitive tasks, reduces errors, and increases productivity, allowing human workers to focus on more complex activities. It is crucial in sectors such as manufacturing, healthcare, and logistics, where precision and reliability are paramount. Advances in automation technology enable smarter, more adaptive systems that improve operational efficiency and reduce costs, driving innovation and competitive advantage in the modern industrial landscape.

Sensors

Industrial sensors are critical devices used to monitor and measure various physical parameters within industrial processes, ensuring efficiency, safety, and automation. They detect and convert physical stimuli such as temperature, pressure, level, flow, and proximity into electrical signals that can be analyzed and acted upon by control systems. Common types of industrial sensors include temperature sensors, pressure sensors, proximity sensors, flow sensors, and level sensors. These sensors enable real-time monitoring and control of machinery and processes, reducing downtime, optimizing performance, and enhancing productivity. Their robustness, accuracy, and reliability make them essential components in manufacturing, processing, and automation industries.

Supply All Ttpes Of Industrial & Electrical Products.

We supply a comprehensive range of industrial and electrical products, catering to diverse sectors and applications. Our inventory includes high-quality components such as motors, sensors, circuit breakers, PLCs, and safety equipment. We also provide tools, cables, connectors, and automation systems. Our products are sourced from leading manufacturers, ensuring reliability and performance. Whether for manufacturing, energy management, or infrastructure projects, we offer solutions that meet stringent industry standards. Our expert team is dedicated to providing tailored advice and support, helping you select the right products for your needs. We are committed to delivering excellence and enhancing operational efficiency.